Operation and care of

Browning BOSS (Ballistic Optimizing Shooting System) Owner's Manual

Browning BOSS (Ballistic Optimizing Shooting System) Owner's Manual

You Are Responsible For Firearms Safety

You Are Responsible For Firearms Safety

The instructions in this owner’s manual are specific to the BOSS® System installed on your new A-Bolt or BAR rifle. You must read and understand the cautions and proper handling procedures outlined in this owner’s manual, and in the owner’s manual received with your rifle before using your new BOSS-equipped rifle. If you are missing the owner’s manual for your rifle, we will send you a free replacement upon request. You can also visit our website at browning.com as many of our owner’s manuals are posted online.

SWEET SPOT CHARTS

Sweet Spot charts for your BOSS-equipped rifle are available at browning.com or by calling (800) 333-3288.

WARNING: THE THREADING ON THE BARREL IS FOR BROWNING BOSS COMPONENTS ONLY. DO NOT INSTALL ANY OTHER DEVICE ONTO THE BROWNING BOSS BARREL. DO NOT INSTALL THE BOSS DEVICE ON ANY RIFLE WHICH IS NOT DESIGNED AND FITTED FOR THE BOSS BY BROWNING. DOING SO MAY CAUSE SERIOUS INJURY OR DEATH TO YOURSELF OR OTHERS, AND CAUSE DAMAGE TO YOUR RIFLE.

IMPORTANT: CAFEFULLY READ THIS ENTIRE OWNER'S MANUAL BEFORE USING YOUR NEW BOSS-EQUIPPED BROWNING RIFLE AND SAVE IT FOR FUTURE REFERENCE.

GENERAL OPERATION

GENERAL OPERATION

The BOSS (Ballistic Optimizing Shooting System) allows you to fine-tune for improved accuracy by modifying the vibrations of your rifle’s barrel using an adjustable weight system.

Every time a rifle is fired, barrel vibrations are set in motion. These vibrations occur in all directions, even back and forth along the axis of the barrel. Our research has confirmed that barrel vibrations are the primary cause of inaccuracy. Barrel vibrations are influenced by many factors such as bullet type, bullet weight, primers, powders and barrel configurations. With the BOSS system, no longer will you need to try a variety of ammunition to obtain acceptable accuracy. You can quickly and easily tune your rifle to get the optimum accuracy for all available factory loads by adjusting the BOSS system to modify barrel vibrations.

The BOSS adjusts the timing of barrel vibrations so the bullet consistently leaves the rifle’s muzzle at the most advantageous time.

Once the BOSS is adjusted to this “Sweet Spot” for a given ammunition, your rifle will consistently deliver extraordinarily tight groups. In fact, BOSS-equipped rifles in a variety of calibers are capable of producing 100 yard, one-hole groups with precision ammunition. The smallest three-shot group obtained during the BOSS development measured an incredible .051" at 100 yards, using factory loaded ammunition.

When adjusted to its Sweet Spot, the BOSS will compensate for slight deviations in ammunition velocity. However, the BOSS will not compensate for poor shooting or flyers caused by low quality bullets and ammunition.

Note: To obtain the highest level of accuracy from your rifle, it is recommended that the rifle bore be cleaned after firing 12-15 rounds. See “Cleaning the Rifle Bore” section in this owner's manual for cleaning procedures.

MUZZLE BRAKE FEATURE

MUZZLE BRAKE FEATURE

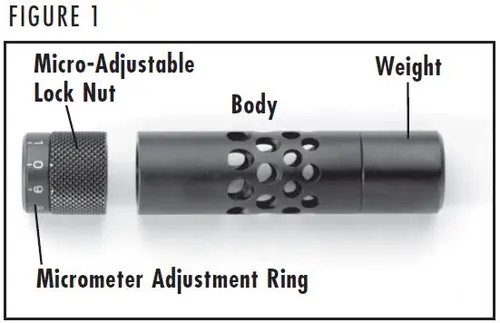

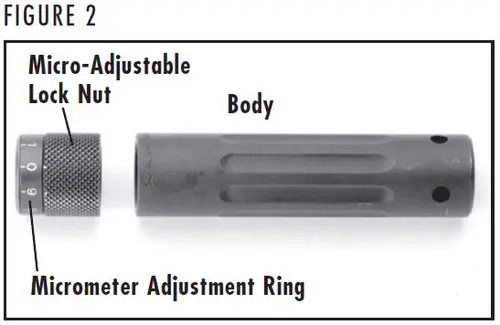

The BOSS is available in two versions, the muzzle brake version (Figure 1) and the CR (conventional recoil) version (Figure 2).

WARNING: THE BOSS WITH RECOIL REDUCING MUZZLE BRAKE PROVIDES SUBSTANTIALLY INCREASED NOISE AND MUZZLE BLAST. ALWAYS WEAR HEARING PROTECTION TO PREVENT HEARING LOSS OR DAMAGE.

The unique exhaust port pattern on the BOSS with muzzle brake provides considerable recoil reduction. Recoil reduction of the BOSS ranges from 30% to 50% — depending on caliber, weight of rifle, etc.

You will experience an increase in noise and concussion (muzzle blast) when a BOSS-equipped rifle is fired. Hearing protectors (shooting ear plugs or muffs) should always be worn to guard against hearing damage when shooting a BOSS-equipped rifle. Wear shooting glasses to protect your eyes from flying particles. Always keep a safe distance between the muzzle of your firearm and any persons nearby, as muzzle blast, debris and ejecting shells could inflict serious injury.

BOSS SPECIFICATIONS

BOSS SPECIFICATIONS

The BOSS body length is 2" for all calibers. The size of the gas vent ports and port pattern is the same for all calibers. The size of the bullet exit opening is the same for all calibers except for the 338 Win. Mag. and 375 H&H. The thread system for the 338 Win. Mag. and the 375 H&H is different from other calibers to rule out the possibility of accidentally switching components and creating an unsafe combination. Do not attempt to interchange these systems. Use only the BOSS intended for your rifle.

The BOSS consists of a micro-adjustable lock nut and body (Figures 1 and 2). The weight is affixed to the body with LOCTITE® thread locking compound. The micro-adjustable lock nut has a micrometer adjustment ring. To obtain the utmost accuracy from your BOSS-equipped rifle, it is very important that the micro-adjustable lock nut and body are always tight.

THE SWEET SPOT

THE SWEET SPOT

Precision accuracy from the BOSS system is achieved by calibrating your rifle caliber and ammunition from a prescribed Sweet Spot setting found on the BOSS Sweet Spot chart. The chart is available separately from this owner’s manual. If you do not have a Sweet Spot chart, call (800) 333-3288 to request one. You can also find Sweet Spot information at browning.com.

The chart lists average, or suggested, Sweet Spot settings. These settings were determined through extensive testing by our Research and Development staff. Sweet Spots may vary between rifles of identical specifications with given ammunition. Even one quarter of a turn away from the Sweet Spot can cause a group to spread out as much as one inch or more. We suggest you use our listed Sweet Spot settings as a starting point in determining the exact Sweet Spot setting for your particular rifle and make changes accordingly.

IMPORTANT: Any change to the BOSS settings may slightly alter your rifles point of impact. It is recommended you set the BOSS Sweet Spot setting before sighting in your rifle for windage and elevation. The BOSS was tested in full turn, ½ and ¼ turn increments. Tighter groups may be achieved with the BOSS tested in other positions. On the Sweet Spot chart, Sweet Spots are listed by both ammunition and rifle model. Settings not listed either do not apply or are for ammunition not yet tested.

PRELIMINARY ADJUSTMENTS

PRELIMINARY ADJUSTMENTS

WARNING: BEFORE PERFORMING BOSS CALIBRATION ADJUSTMENTS TO YOUR RIFLE, MAKE SURE YOUR RIFLE IS COMPLETELY UNLOADED. REMOVE THE MAGAZINE, CHECK THE ACTION AND CHAMBER FOR CARTRIDGES. KEEP THE MUZZE POINTED IN A SAFE DIRECTION. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

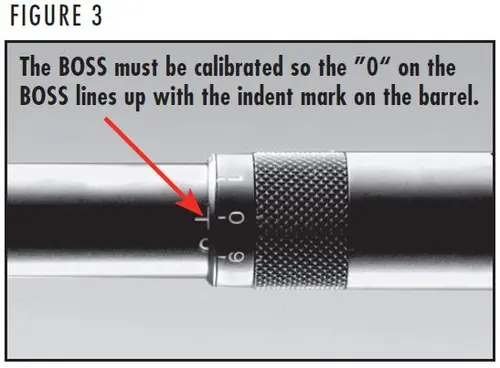

Before setting your Sweet Spot, it is important that your BOSS be calibrated with the barrel (Figure 3). This will ensure that your rifle is consistent with those tested by our Research and Development staff when the BOSS Sweet Spots were initially determined.

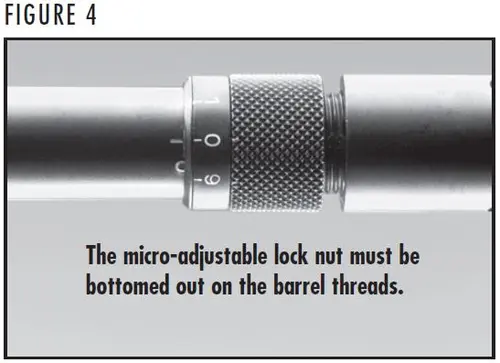

To find out if your BOSS needs to be recalibrated, loosen the micro-adjustable lock nut and turn it until it bottoms out on the threads of the barrel — or will not loosen any further (Figure 4). If your BOSS is calibrated, the “0” mark on the micrometer adjustment ring will line up with the longitudinal index mark on the barrel as shown in Figure 4. If the “0” mark is not aligned with the longitudinal index mark, you will need to calibrate your BOSS.

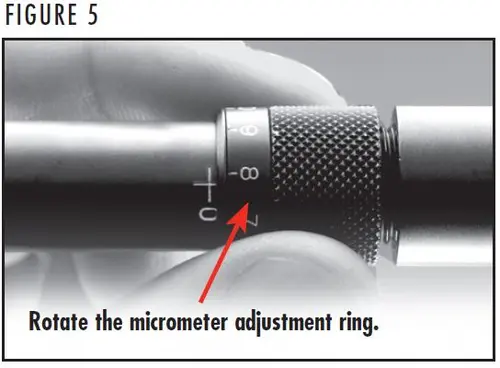

To calibrate the BOSS, move the micrometer adjustment ring on the bottom of the micro-adjustable lock nut so the “0” on the split ring is aligned with the longitudinal index mark on the barrel. To adjust the micrometer adjustment ring, insert your fingernail or a small pointed object in the split of the ring and rotate the ring until the “0” mark on the split ring is aligned with the longitudinal index mark on the barrel (Figure 5).

IMPORTANT: It is not necessary to calibrate your BOSS with each change in Sweet Spot settings. However, you should check the BOSS periodically to assure proper alignment.

WARNING: BEFORE SETTING THE SWEET SPOT TO YOUR RIFLE, MAKE SURE YOUR RIFLE IS COMPLETELY UNLOADED. REMOVE THE MAGAZINE, CHECK THE ACTION AND CHAMBER FOR CARTRIDGES. KEEP THE MUZZE POINTED IN A SAFE DIRECTION. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

SETTING YOUR RIFLE'S SWEET SPOT

SETTING YOUR RIFLE'S SWEET SPOT

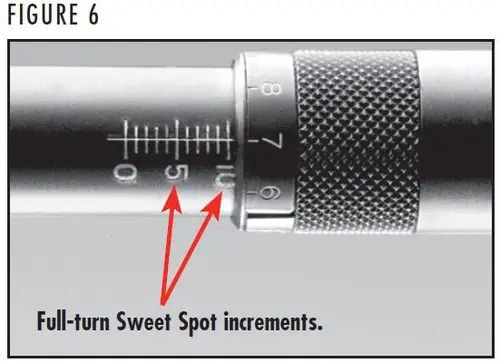

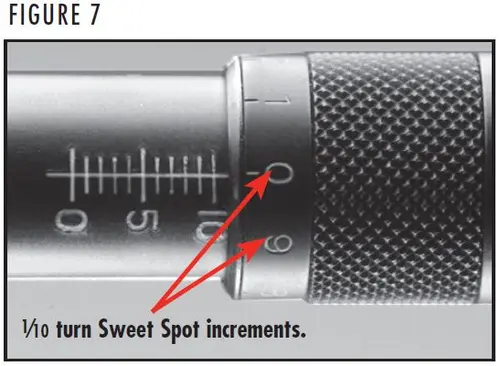

Full-turn Sweet Spot settings or graduations are numbered 1-10 and inscribed on the barrel of your rifle (Figure 6). Smaller 1⁄10 turn increments are inscribed on the micrometer adjustment ring (Figure 7). To set the Sweet Spot, the micro-adjustable lock nut is turned either clockwise or counterclockwise until it is aligned with the desired Sweet Spot number inscribed on your rifle’s barrel. One full revolution of the micro-adjustable lock nut indicates one full change in setting, or one index mark on the barrel. 1⁄10 turn increments are set by rotating the micro-adjustable lock nut until the desired setting lines up with the index mark on the barrel.

IMPORTANT: When adjusting the Sweet Spot, make sure you grip the knurled surface of the lock nut. The knurled portion of the micro-adjustable lock nut and micrometer adjustment ring must rotate together to ensure a precise Sweet Spot setting and to retain proper calibration.

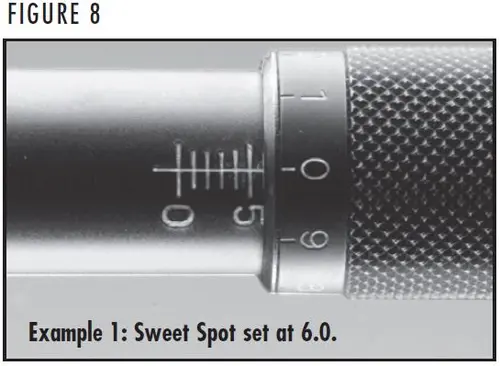

EXAMPLE 1

1. Suppose you have an A-Bolt rifle in 270 Win. caliber and are sighting in with 150 grain cartridges. Referring to the Sweet Spot chart, you will find the average Sweet Spot to be 6.0 for an A-Bolt in 270 Win. with 150 grain ammunition.

2. After having made sure your BOSS is calibrated properly on the barrel, rotate the micro-adjustable lock nut counterclockwise six full revolutions. The edge of the micrometer adjustment ring should line up, or rest, on the marking for 6.0 on the barrel of the rifle.

3. Since the Sweet Spot setting is listed at 6.0, the 0 inscribed on the micrometer adjustment ring should line up with the index mark or longitudinal line on the barrel (Figure 8).

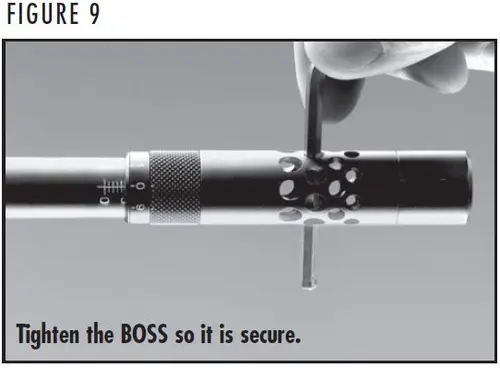

4. Tighten the body of the BOSS so it is secure against the micro-adjustable lock nut. Use the special wrench supplied with your rifle. On the muzzle brake BOSS insert the wrench through one end of an exhaust port and out through another. It is recommended to insert the wrench through the smallest set of ports possible. On the BOSS CR insert the wrench through a port on the end of the BOSS and out through another (Figure 9). Turn clockwise until the body and micro-adjustable lock nut are tight.

WARNING: BE SURE TO REMOVE THE WRENCH FROM THE BOSS EXHAUST PORTS BEFORE FIRING YOUR RIFLE. FAILURE TO DO SO MAY CAUSE SERIOUS INJURY OR DEATH TO YOURSELF OR OTHERS, AND CAUSE DAMAGE TO YOUR RIFLE.

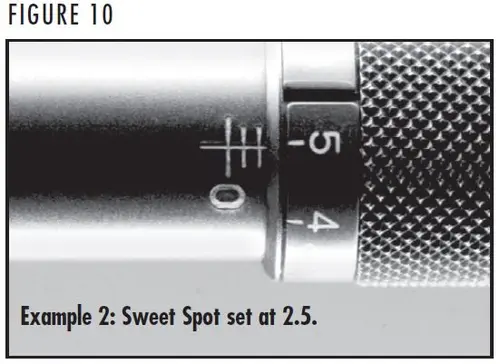

EXAMPLE 2

1. Suppose you have a 243 Win. BAR rifle and are using 100 grain cartridges. Referring to the Sweet Spot chart, you will find the average Sweet Spot to be 2.5.

2. Calibrate your BOSS and rotate the micro-adjustable lock nut counterclockwise until the edge of the micrometer adjustment ring lines up, or rests, on the marking for 2.0 on the barrel.

3. Since the Sweet Spot is listed as 2.5, the 5 inscribed on the micrometer adjustment ring should line up with the index mark or vertical line on the barrel (Figure 10).

4. Using the special wrench, tighten the body of the BOSS so it is secure against the lock nut as explained previously. Your BOSS system is now calibrated for 100 grain ammunition using a 243 Win. BAR rifle.

MORE PRECISE ADJUSTMENTS

MORE PRECISE ADJUSTMENTS

If you desire to further experiment and possibly obtain even tighter groupings, turn the micro-adjustable lock nut ¼ of a turn clockwise and fire your rifle at a safe target. If the group opens up (gets larger), turn the micro-adjustable lock nut counterclockwise and sight in at different ¼ turns until you are satisfied with your groupings. Sweet Spot settings may vary between rifles of identical specifications with a given ammunition. As in any sighting-in process, the best results are obtained through systematic trial and error. You may need to retune the BOSS should you decide to shoot ammunition of different brands, lots and / or types.

Be sure to keep a detailed record of your rifle’s Sweet Spot settings, especially if you use

WARNING: WHEN ADJUSTING THE SWEET SPOT, NEVER SET THE BOSS BEYOND THE 10 SETTING. THE BOSS COULD BECOME LOOSE, MISALIGNED OR DISENGAGED WHEN FIRING THE RIFLE RESULTING IN SERIOUS INJURY OR DEATH TO YOURSELF OR OTHERS, AND CAUSE DAMAGE TO YOUR RIFLE.

IMPORTANT: Each time you set the Sweet Spot, the body of the BOSS must be tight against the micro-adjustable lock nut. Failure to keep the components tightly locked will adversely affect accuracy.

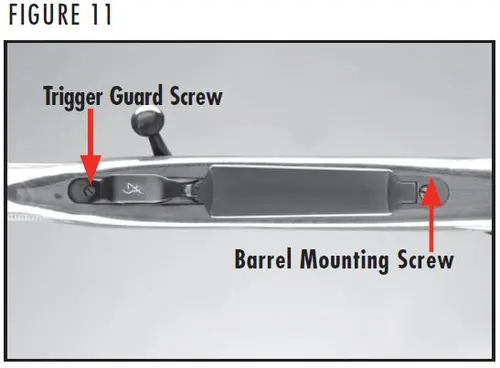

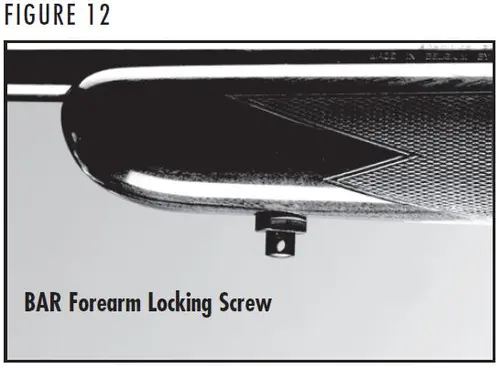

IMPORTANT: The barrel mounting screw and trigger guard screw on the A-Bolt should also be fully tightened (Figure 11). If the barrel mounting screw and trigger guard screw are loose on your A-Bolt, tighten the barrel mounting screw before tightening the trigger guard screw. On the BAR, the forearm locking screw should be kept fully tightened (Figure 12) to obtain, and retain, the best possible accuracy from your rifle.

NYLON LOCKING DEVICE

NYLON LOCKING DEVICE

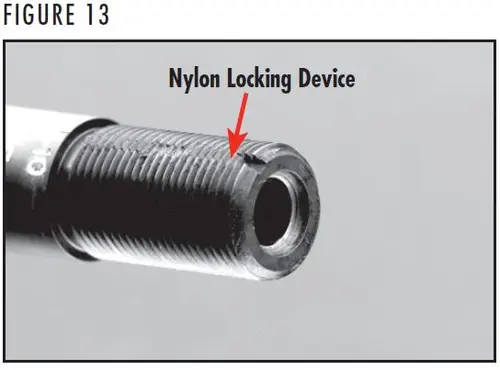

A strip of nylon in the threaded portion of the barrel helps keep the BOSS body properly positioned at the Sweet Spot setting. This locking device keeps the components tight to the barrel, which is essential for optimum accuracy (Figure 13). The nylon may become worn with prolonged use and may require replacement. Replacement nylon locks are available from the Browning Parts Department in Arnold, Missouri.

CARE OF YOUR BOSS-EQUIPED RIFLE

CARE OF YOUR BOSS-EQUIPED RIFLE

IMPORTANT: The BOSS is a precision instrument. In order for the BOSS system to operate effectively, it is extremely important that your rifle remains in its original purchase condition. It is necessary for the barrel to remain free-floating and the action properly bedded.

The above statement holds true either for the A-Bolt or BAR. To check for adequate barrel clearance, it is recommended that a piece of paper, folded once, be able to pass between the barrel and stock without any interference. If the barrel is not free-floating, take your rifle to a qualified gunsmith, a local recommended Browning Firearms Service Center or send it to the Browning Service Department in Arnold, Missouri. Special rubber bedding in the recoil lug area of your BOSS-equipped A-Bolt rifle is installed at the factory and aids greatly in improving accuracy. (Rubber bedding is not needed for the BAR.) If you have any modifications made to your stock, make sure the rubber bedding has not been altered. If the rubber bedding on your rifle has been modified, send your rifle to the Browning Service Department in Arnold, Missouri.

WARNING: BEFORE PERFORMING CLEANING PROCEDURES, MAKE SURE YOUR RIFLE IS COMPLETELY UNLOADED. REMOVE THE MAGAZINE, CHECK THE ACTION AND CHAMBER FOR CARTRIDGES. KEEP THE MUZZE POINTED IN A SAFE DIRECTION. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

WARNING: WEAR EYE PROTECTION WHEN DISASSEMBLING AND CLEANING YOUR RIFLE TO PREVENT SOLVENTS OR OTHER AGENTS FROM CONTACTING YOUR EYES, RESULTING IN INJURY.

WARNING: KEEP ALL AMMUNITION AWAY FROM THE CLEANING AREA. NEVER TEST THE MECHANICAL FUNCTION OF YOUR RIFLE WITH LIVE AMMUNITION. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

WARNING: MOST SOLVENTS ARE HIGHLY FLAMMABLE. WEAR EYE PROTECTION A PRACTICE APPROPRIATE SAFETY MEASURES WHEN WORKING WITH SOLVENTS TO AVOID SERIOUS INJURY.

CLEANING THE BORE

CLEANING THE BORE

To maintain the utmost accuracy from your BOSS-equipped rifle, or any rifle, extensive testing has proven that the rifle bore must be cleaned after every 12 to 15 rounds.

We highly recommend that your rifle be cleaned with the BOSS installed on your barrel. On the A-Bolt, remove the bolt and clean the rifle from the breech end. The BAR, by design, must be cleaned from the muzzle end. Use a rod guide and extra care when cleaning to avoid damaging the muzzle crown.

Modern cartridge jackets are made mainly of copper and zinc. These metals glide easily and prolong barrel life; however, residues from copper and zinc stick to the barrel and require more frequent cleaning. As top benchrest shooters have known for decades, copper solvent is the key to cleaning a barrel for optimum accuracy. The recommended cleaning procedure is as follows:

1. Clean the bore with a good powder solvent to remove all traces of powder residue. Performing this step before the application of a copper solvent will prevent the bore from refouling with copper so readily.

2. Swab the bore with a good copper solvent using the manufacturer’s recommended procedures. After neutralizing the solvent, generally with oil, it is important to swab the bore dry to reduce copper buildup.

NOTICE! DO NOT USE SOLVENTS OF DIFFERENT MANUFACTURERS CONCURRENTLY. A CHEMICAL REACTION MAY RESULT THAT WILL CORRODE EVEN STAINLESS STEEL BARRELS. IT IS IMPORTANT TO FOLLOW THE MANUFACTURER’S RECOMMENDATIONS EXACTLY.

3. If necessary, the BOSS may be removed to facilitate cleaning your rifle.

NOTICE! WHEN CLEANING THE BAR WITH THE BOSS REMOVED, THE PLASTIC CAP (CROWN AND ACCURACY PRESERVER) PROVIDED WITH THE RIFLE SHOULD ALWAYS BE USED TO PROTECT THE MUZZLE CROWN. ALWAYS MAKE SURE THE CAP USED MATCHES THE CALIBER OF THE RIFLE BEING CLEANED. THE CALIBER IS MARKED ON THE END OF THE CAP.

Clean the BOSS by unscrewing the body and micro-adjustable lock nut from the rifle. With the components disassembled, wipe each component with oil. Browning Oil is excellent for this application. Lightly oil all threads and make sure the exhaust ports are free of obstructions.

NOTICE! REMEMBER TO REMOVE THE PLASTIC CAP WHEN REASSEMBLING THE BOSS ON THE BAR.

4. Reassemble your BOSS by screwing on the micro-adjustable lock nut and then the BOSS body. After taking apart the BOSS, it will be necessary to reset the Sweet Spot.

WARNING: MAKE CERTAIN ALL CLEANING PATCHES ARE REMOVED FROM THE BARREL AND EXHAUST PORTS IN THE BODY OF THE BOSS BEFORE FIRING YOUR RIFLE. FAILURE TO DO SO MAY CAUSE SERIOUS INJURY OR DEATH TO YOURSELF OR OTHERS, AND CAUSE DAMAGE TO YOUR RIFLE.

5. After cleaning the bore, it is recommended two fouling shots be fired before firing for extreme accuracy. Additionally, it is recommended the rifle be allowed to cool after every three shots.

SERVICE OR REPAIR

SERVICE OR REPAIR

If your firearm should require service or repairs, we suggest you first contact a local recommended Browning Firearms Service Center.

To locate a service center visit browning.com, contact our Customer Service Department or your Browning firearms dealer for the address of the Service Center nearest you. Otherwise, you may send your firearm directly to our Service Department in Arnold, Missouri.

Parts listings, Firearm Service Center lists, service procedures, service/repair form and general product information are also found on the internet at browning.com. For technical questions about your firearm or service, contact:

United States customers contact:

Browning Firearm Status and Technical Service

3005 Arnold Tenbrook Rd

Arnold, MO 63010-9406

Phone: (800) 322-4626

Canadian customers contact:

Browning Canada Sports Ltd/Ltée

5583 Chemin St-François

St-Laurent, Quebec H4S 1W6

Phone: (514) 333-7261

When returning your firearm for servicing, you must do the following:

1. Be sure it is completely unloaded.

2. Remove the scope or other optics.

3. Package it securely in a cardboard container.

4. Enclose the service/repair form available at browning.com or a letter that clearly describes the trouble experienced, the ammunition used and the repairs desired. Also include your name, email address (if possible) and a daytime phone number where you can be reached.

5. If convenient, send a copy of the service/repair form or letter to us separately.

6. Never return ammunition with your firearm. It is against postal and most commerce regulations.